Stainless Steel Explosion Proof Electric Motorized Ball Valves mount between standard ANSI 150 flanges. These dual certified fire safe explosion proof valves are power-to-open and power-to-close and stay in last known position with loss of power.

These 316 stainless steel valves come fitted with an AT series pneumatic actuator. Choose your option: on/off, regulation or intelligent.

Stainless Steel

Stainless steel flanged ball valves are designed to be safe for use in various types of piping systems. They can be used for air, gaseous and liquid applications and are bubble-tight. These valves are easy to install and do not require extensive maintenance. They also work well with a variety of materials and can be used in environments with high temperatures and pressures.

When choosing the right flanged ball valve unit, it is important to look into particular factors. This ensures that you obtain the best results from the device in your specific projects. The main factor to consider is the type and design of the valve unit.

Make sure the manufacturer you choose has a good track record of producing quality devices. It is also important to ensure that the company offers an ideal warranty on their products. This demonstrates their confidence in the quality of their product and gives customers peace of mind.

PTFE Seat

Valve seats, washers and gaskets are essential to the performance of the valve unit. They offer a cushion when the valve closes and reduce the amount of shock the valve experiences. This prolongs its life and ensures that it maintains a tight seal.

PTFE is one of the most popular choices for ball valve seat material. It offers ultra-low friction, excellent chemical resistance and a wide operating temperature range. The downside of virgin PTFE is that it can be attacked by some chemicals, such as those that attack glass. PTFE seats can be reinforced with glass fiber or carbon to increase its ability to withstand these types of attacks.

Another option for a seat is PEEK, which has an even lower coefficient of friction and can resist chemicals that attack glass. It can also withstand high temperatures, up to 550 degrees Fahrenheit. It is a good choice for nuclear service, tobacco industry and other applications where TFE is prohibited.

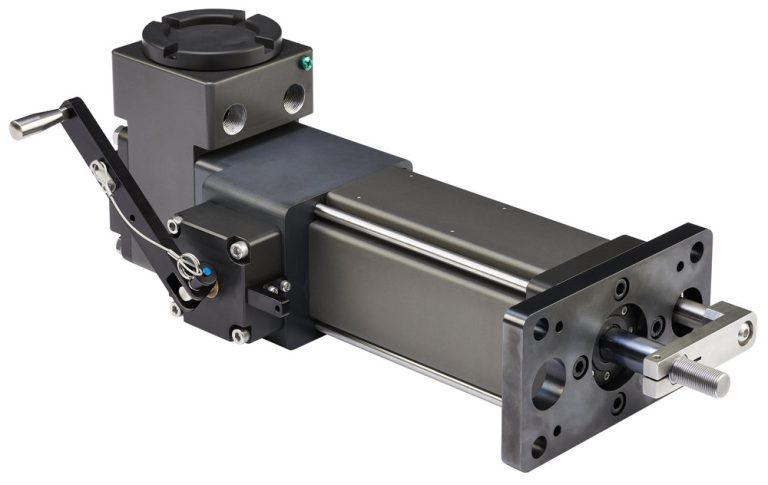

Pneumatic Actuator

Pneumatic actuators convert compressed air into mechanical motion. They use regular air or pressurized gas and direct it toward a mechanical component, such as a piston or gear, which performs the action. They don’t require electricity or ignition to operate, making them suitable for potentially explosive environments.

Depending on their design, pneumatic actuators produce either linear or rotary motion. Linear-style actuators offer a limited range of linear motion, while rotary-style actuators allow for up to 360 degrees of rotation. They can be further categorized by their mechanism, such as pistons, diaphragms, yokes, and vane-style actuators.

Explosion proof pneumatic actuators feature a flameproof enclosure that keeps the equipment and the surrounding environment separate. They’re also compatible with explosion proof accessories, such as a solenoid valve and an electric pneumatic valve positioner. They’re available in flange connection type ball valves for easy installation.

Safety Devices

Electricity makes the world run by powering computers and recharging portable handheld devices, but it can also be dangerous. To prevent injuries, safety interlock switches, light curtains and other electrical equipment help ensure safe operations in hazardous areas.

Typical electrical equipment creates tiny electric arcs and sparks in switches, motor brushes and connectors. In some situations, these sparks can ignite an explosive atmosphere. To prevent this, explosion proof equipment uses bulkier housing that can withstand an internal blast.

In order to qualify as explosion proof, a piece of equipment must have an intrinsically safe circuit system that cannot generate ignition energy in an explosive atmosphere. This can be achieved through limiting available electrical currents, voltages and heat. It can also be accomplished through limiting component spacing and eliminating the ability of dust to short circuit an electrical wire.Explosion Proof Stainless Steel Flanged Ball Valves